FEATURED PROJECT 2

LOAD TESTING

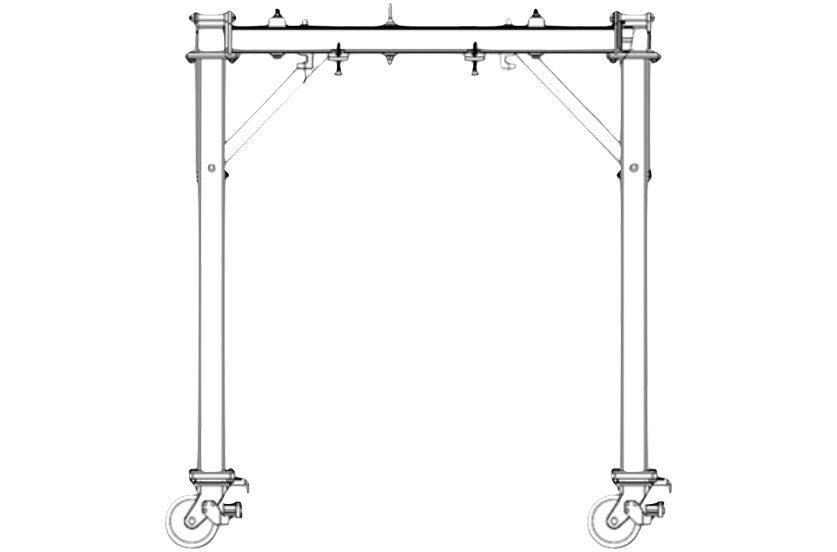

Aircraft Factory Assembly Frame.

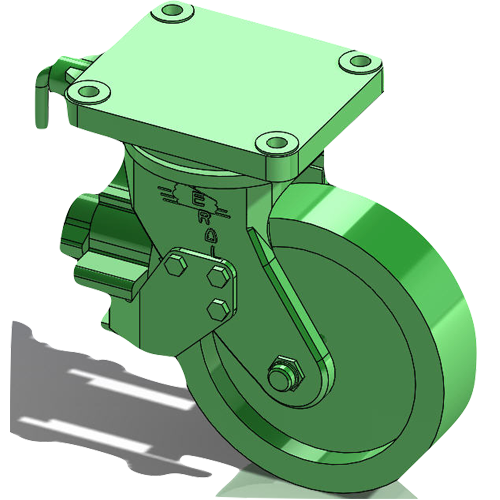

Requirements: Weld, 100% Weld Visual Inspection, Create and Coordinate Load Test and Design Specialized Load Interfaces, Paint, Final Assembly with calibrated torque requirement

HIGHLIGHTS

Material: Carbon Steel

Fabrication Software: Solidworks, TruTops Boost, MasterCam, PC-DMIS, DISCUS

Fabrication Processes: Laser Cutting, Lathe, Manual Mill, GTAW

Inspection Methods: Visual Inspection, Certified Load Testing, Laser Scanning

“Thank you DFI for being well prepared and helping us complete all the proof loads in one day. It was a pleasure to meet Andrew, Michael, Greg, and Jesus. It is no easy task to move around 800 lbs of proof load fixture but you guys made it look easy.”